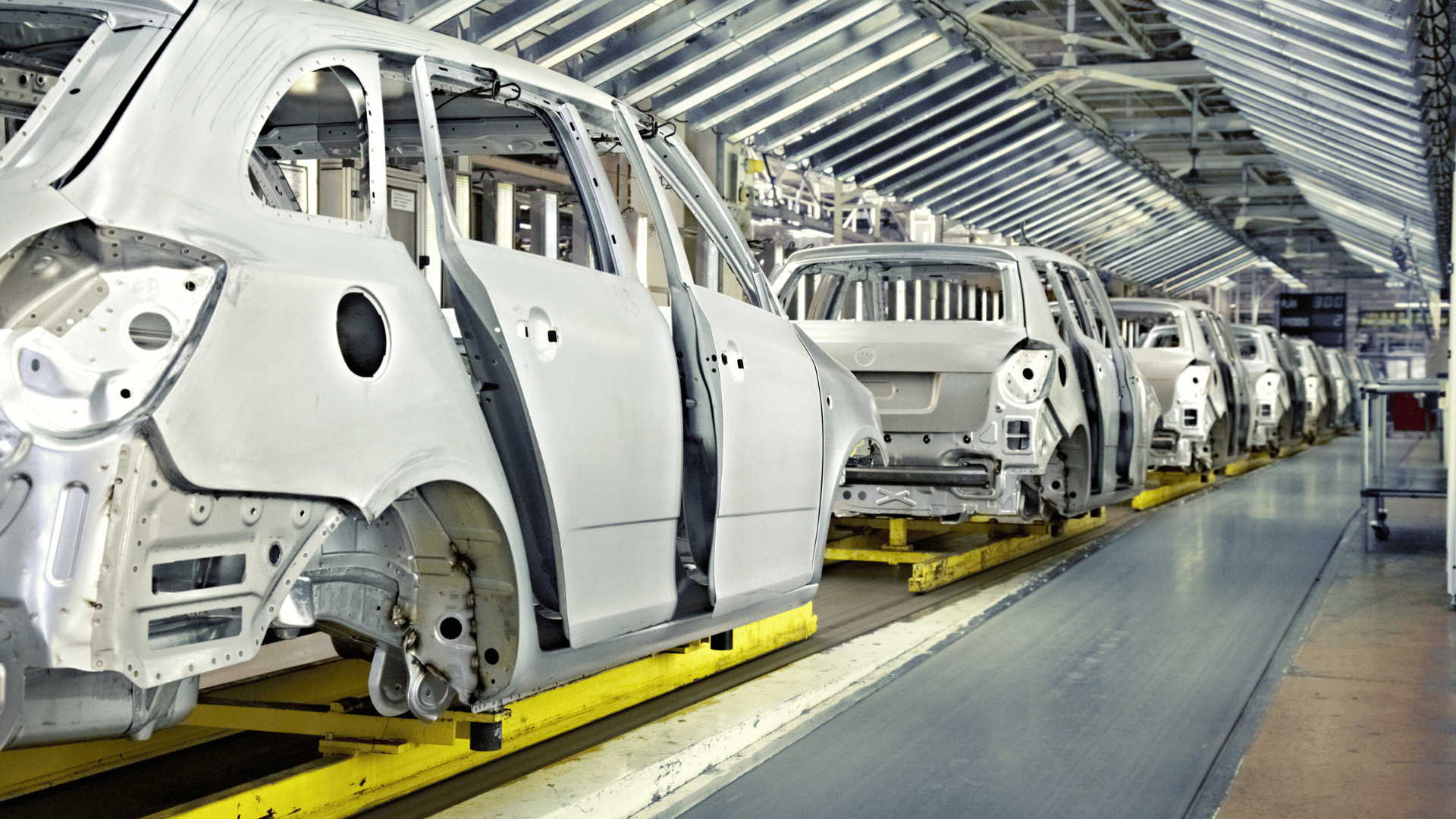

A leading electronics manufacturing company aimed to boost efficiency, reduce operational costs, and streamline production through advanced automation. Their traditional setup relied heavily on manual labor, leading to inconsistent workflows and frequent downtime. To overcome these challenges, they sought a fully automated, data-driven approach to optimize their processes.

Challenges Faced

- Heavy reliance on manual processes caused inefficiencies and increased operational costs.

- Frequent production downtime due to workflow inconsistencies.

- Lack of real-time monitoring and predictive analytics for proactive decision-making.

Implementation

Symbiotic Automation designed and implemented a comprehensive automation system, integrating AI-powered control systems, Industrial IoT (IIoT), and robotics to optimize manufacturing operations.

Key Implementations

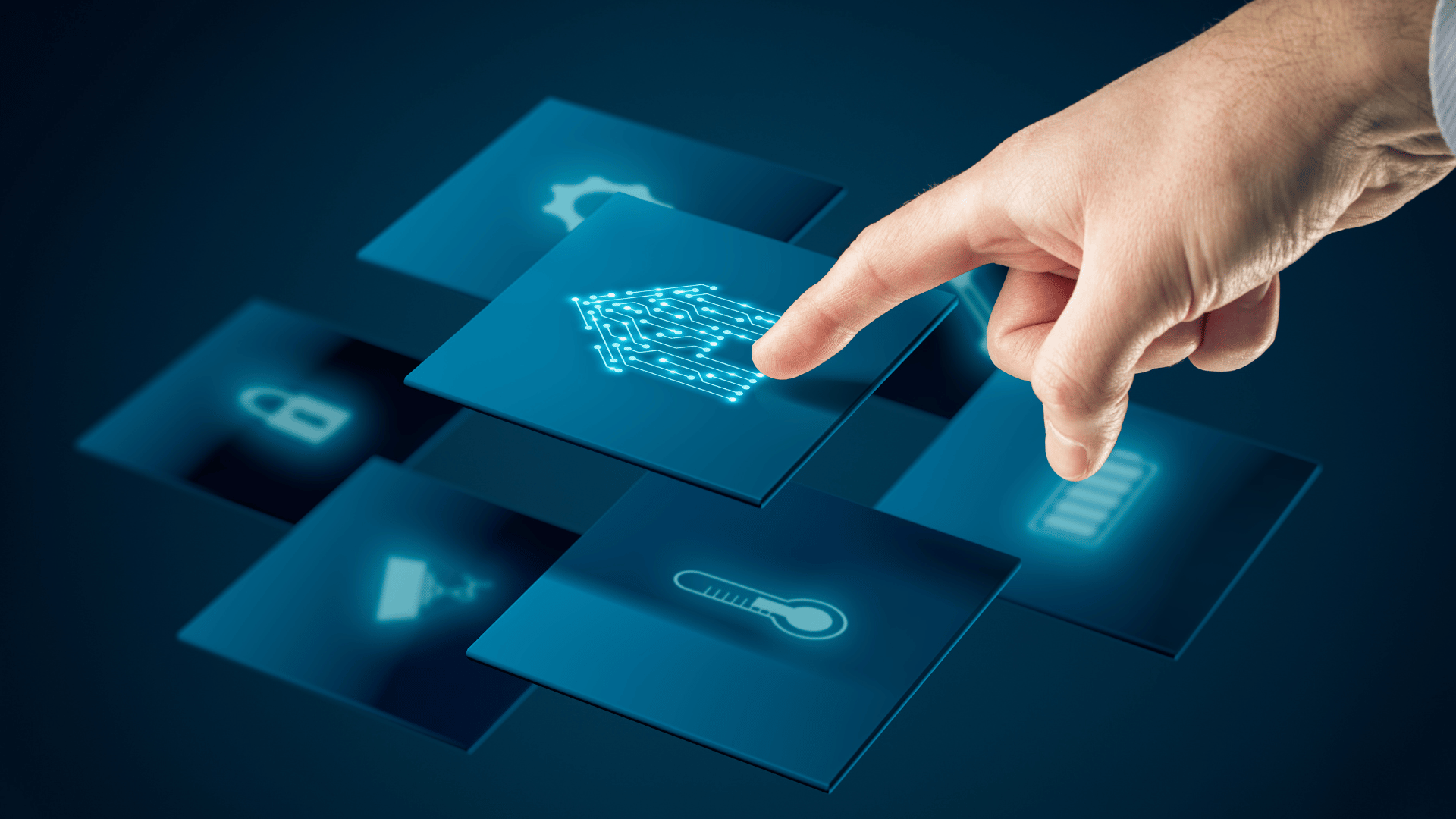

- Industrial IoT (IIoT) – Deployed real-time monitoring sensors for data collection.

- AI-based Predictive Analytics – Improved decision-making and reduced errors.

- Automated Control Panels & Robotics – Enhanced production precision and reduced human intervention.

- Cloud-Based Data Integration – Enabled remote monitoring and workflow optimization.

Outcomes & Benefits

- 30% increase in production efficiency through automation.

- 40% reduction in downtime with real-time data-driven decisions.

- Improved product quality with precise automated control.

- Scalability & Future-Ready – Easy expansion into other production lines.

Future Scope

With automation successfully integrated, the company is now exploring AI-driven