Predictive Maintenance

Utilize AI-driven predictive maintenance to monitor equipment health, prevent failures, reduce costs, and ensure seamless industrial operations.

Stop Failures Before They Happen

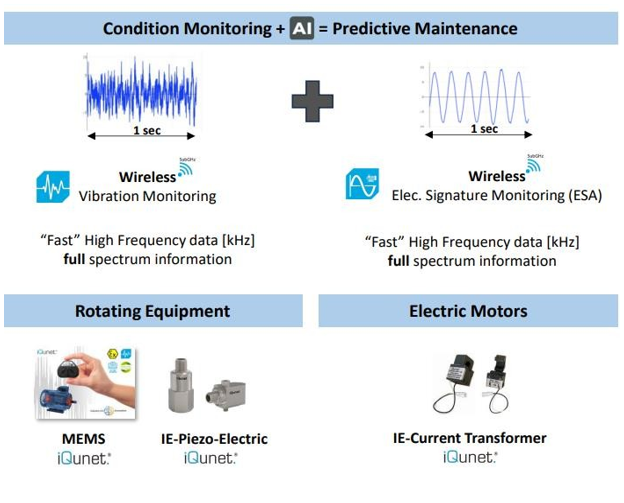

Symbiotic’s predictive maintenance solution – powered by iQunet’s wireless condition monitoring system – detects early signs of machine failure using real-time sensor data and embedded AI at the edge. This fully on-premise solution ensures data privacy and local storage, giving your team complete ownership of sensor data while eliminating the need for cloud dependency.

To ensure seamless operations, our system can be fully integrated with existing HMI/SCADA platforms via OPC UA, enabling real-time visibility and centralized control without disrupting your current setup.

How It Works

- Wireless sensors monitor vibration, temperature, and other machine indicators

- Embedded AI detects anomalies and predicts early-stage faults

- Maintenance teams receive instant, actionable alerts

- Historical trend data supports long-term reliability planning

What Makes Us Different?

- AI-Embedded Edge Computing

- On-Premise Architecture

- Free Sensor Data

- Seamless Interoperability

Key Benefits

- Early Fault Detection

- Reduced Downtime and Maintenance Costs

- Extended Equipment Life

- Improved Scheduling and Resource Allocation

- AI-Driven Insights

- Safer and More Reliable Operations

Enquire Now

Share your details and receive a custom quote instantly

Need more help?

Get In Touch With Us

080 41321600

99006 83800

Everything You Need to Know

Most Popular Questions.

Get answers to your Predictive Maintenance and discover how smart solutions can enhance efficiency, productivity, and sustainability.

Predictive maintenance uses AI, sensors, and data analytics to predict equipment failures before they happen, reducing downtime.

By preventing unexpected breakdowns, predictive maintenance reduces repair costs, extends asset life, and minimizes production disruptions.

Manufacturing, energy, aviation, logistics, and healthcare benefit from predictive maintenance to improve operational efficiency.

Preventive maintenance follows a fixed schedule, while predictive maintenance analyzes real-time data to determine when service is actually needed.

Yes, our predictive maintenance solutions can be integrated with existing IIoT platforms, SCADA, and ERP systems for seamless operation.